DONCHAMP® Cast Acrylic

Laser Cutting Suggested Procedure

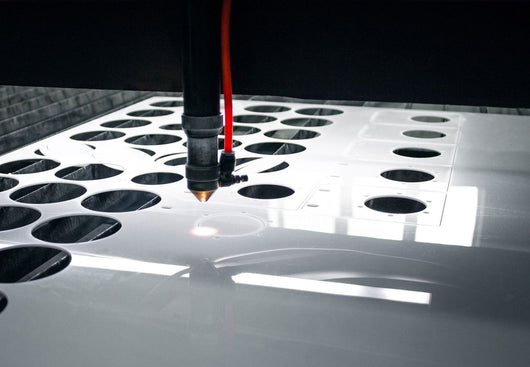

In normal conditions, CO2 lasers can easily cut DONCHAMP® acrylic sheet. The polished gloss cut edges obtained on laser cutting, can sometimes vary in its quality, depending on material grade, material thickness, and colour. DONCHAMP suggests an evaluation prior to commercial cutting and that the laser is adjusted to meet the conditions. DONCHAMP understands that CO2 lasers normally have a power range of between 250 and 1000 watts. It can be difficult to suggest a certain laser performance for individual applications, since this depends on certain factors, such as the purity and water content of the laser gas, the gas throughput, condition of the IR optics.

DONCHAMP has performed tests on DONCHAMP® acrylic sheets in varying

thickness and different degrees of edge finish (gloss) using 300 W to 700 W lasers.

Depending on the laser power, the feed rates will need adjustments to the sheet

thickness to achieve the required level of gloss cut edges, where with thinner sheets,

we suggest higher feed rates & for thicker sheets we suggest lower feed rates. If the

feed is too slow, we have experienced that dull edges will result & in cases where

the feed rate may be too fast, chattered / gouges can appear. In these instances, the

reason for this appearance may also be the result of inaccurate focusing of the laser

beam. DONCHAMP suggests 10W laser power per 1mm sheet thicknesses = high

cutting quality (20-25mm max thickness).

Also, in DONCHAMP’s experience, the edges on sheets of higher thickness will most often appear to be slightly oblique. DONCHAMP suggests focusing the laser beam on the centre of the sheet thickness. If the beam impinges above or below this point, V-shaped or on in particular thick sheets, concave cut edges could be resulting. To obtain edges as rectangular as possible, DONCHAMP suggests adjusting the following focal lengths:

Also, in DONCHAMP’s experience, the edges on sheets of higher thickness will most often appear to be slightly oblique. DONCHAMP suggests focusing the laser beam on the centre of the sheet thickness. If the beam impinges above or below this point, V-shaped or on in particular thick sheets, concave cut edges could be resulting. To obtain edges as rectangular as possible, DONCHAMP suggests adjusting the following focal lengths:

Up to 6 mm thickness:

2 ½” (63.5mm) lens

6 to 15 mm sheet thickness:

5” (127mm) lens

Over 15 mm sheet thickness:

10” (2540mm) lens

Between 5” (127mm) and 10” (2540mm) focal length, the laser optics should have no

influence on the appearance of the cut edge, but it will affect the angularity of the cut,

along with the focal position & the sheet thickness.

To prevent smoke gas splashing back on the lens, minimal compressed air purge

(with oil and water separator) at the laser head is enough. The vapours generated in

the cutting of the DONCHAMP® panel, require extraction from the beam exit side,

(For example: with slight suction or air purge as well). Also, with the mentioned air

purge or vapour extraction, existing systems equipped with nozzles at the laser head

for purging with inert gas, such as nitrogen, for example.

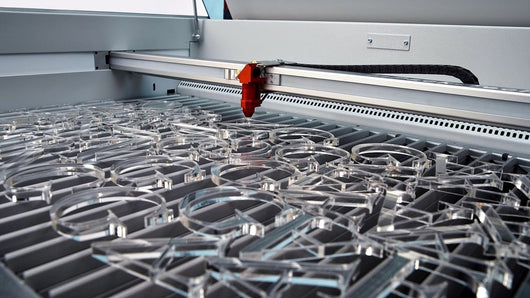

This is not necessary for standard cuts, where it is useful for precision parts. Laser beam flashback can be due to the flat support material with the DONCHAMP® acrylic, causing an optical impairment and can contaminate the lens. The alternative use of grid supports can usually prevent this. Utilizing the air assist feature on the laser will reduce the instance of flare-ups when working with flammable materials such as acrylic & wood. When cutting DONCHAMP® acrylic, we suggest to always use the nozzle with the largest diameter & if possible reduce the air assist to a max. of 0.2 bar. This will enable the DONCHAMP® acrylic sufficient time to completely cool, enabling a high gloss finish. We suggest that when using a small dameter nozzle, or if the air pressure is too high, the resulting cut edge finish will be a dull, hazy or matte due to its rapid cooling. Utilising an appropriate exhaust system is important when cutting DONCHAMP acrylic. This is mainly due to the vapours within the machine being dangerous to the operator, the laser & the environment. Good ventilation is always necessary to achieve a perfect cut, while a lack of ventilation could cause vapours to ignite & start a fire.

We suggest that a speed or power controlled laser beams will improve the cut edge finish, EG. corners, angles. A controlled laser beam can cut complex of shapes. Appropriate systems can cut thermoformed three dimensionally parts. We suggest that any stress generated close to the cut edges will need relieving, by further annealing the DONCHAMP® acrylic part, to eliminate the risk of crazing.

This is not necessary for standard cuts, where it is useful for precision parts. Laser beam flashback can be due to the flat support material with the DONCHAMP® acrylic, causing an optical impairment and can contaminate the lens. The alternative use of grid supports can usually prevent this. Utilizing the air assist feature on the laser will reduce the instance of flare-ups when working with flammable materials such as acrylic & wood. When cutting DONCHAMP® acrylic, we suggest to always use the nozzle with the largest diameter & if possible reduce the air assist to a max. of 0.2 bar. This will enable the DONCHAMP® acrylic sufficient time to completely cool, enabling a high gloss finish. We suggest that when using a small dameter nozzle, or if the air pressure is too high, the resulting cut edge finish will be a dull, hazy or matte due to its rapid cooling. Utilising an appropriate exhaust system is important when cutting DONCHAMP acrylic. This is mainly due to the vapours within the machine being dangerous to the operator, the laser & the environment. Good ventilation is always necessary to achieve a perfect cut, while a lack of ventilation could cause vapours to ignite & start a fire.

We suggest that a speed or power controlled laser beams will improve the cut edge finish, EG. corners, angles. A controlled laser beam can cut complex of shapes. Appropriate systems can cut thermoformed three dimensionally parts. We suggest that any stress generated close to the cut edges will need relieving, by further annealing the DONCHAMP® acrylic part, to eliminate the risk of crazing.

Speed: Lower gauge DONCHAMP® acrylic panels require lower/slower speed/feed

rates. If the feed is too slow, dull edges may occur. If the speed/feed rate is too fast,

striation and gouges will appear.

Focusing: In assisting with accuracy, the focus is on the centre of sheet thickness, otherwise it will be result in a dull finish edges, stepping & gouging. If the focus infringes above or below this point, a V-shape edge, or with thicker sheets a concave cut edge, will most likely occur.

Focusing: In assisting with accuracy, the focus is on the centre of sheet thickness, otherwise it will be result in a dull finish edges, stepping & gouging. If the focus infringes above or below this point, a V-shape edge, or with thicker sheets a concave cut edge, will most likely occur.