Green ✔ Tick™ cast acrylic sheet is a recent proprietary development in specialty acrylics, utilizing innovative technology by incorporating both recycled & virgin raw materials, into a premium quality finished product.

Green ✔ Tick™ are leaders in the innovation of acrylic sheet products, with our production management identifying a recycling process, enabling the reproduction of a sustainable acrylic sheet product. Green ✔ Tick™ acrylic invested in the further research to create a proprietary process of regeneration of acrylic sheet waste, into a high performing cast acrylic sheet product.

Green ✔ Tick™ is enabling the new generation of sustainable acrylic production, creating an environmental choice with the goal of assisting in the protection of our planet. The Green ✔ Tick™ proprietary process, simply enables scraps/waste to be chemically altered, further enabling the initial product to be regenerated back into a new sustainable finished material.

Environmental factors

We believe that the use of waste into society is an important process in addressing a sustainable environmental future. Currently plastic products are widely regarded as throw away items, where Green ✔ Tick™ enables:● Utilisation of scrap/waste, giving a new life to a finished product.

● Reduced consumption of new raw materials.

● Reduced demand for landfill.

● Contribution to the protection of the environment.

● Free of VOC & HFC.

● The GreenTick manufacturing process, substantially reduces our environmental impact.

● GreenTick contains no hazardous substances such as heavy metals, hormone type products (bisphenol A) & no CFC or PCB like products.

Facts

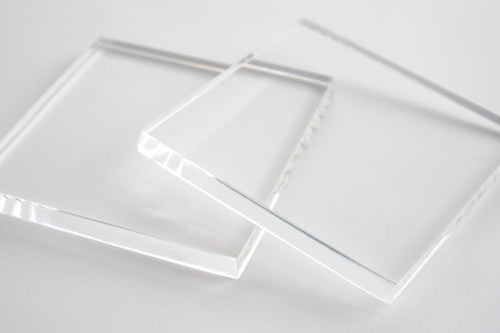

Green ✔ Tick™ acrylic has excellent optical clarity, good mechanical properties, exceptional surface finish, is simple to fabricate (cut, bend & polish), superb ink & paint adhesion, whilst virtually eliminating the current environmental issue, by utilizing waste & scrap.Green ✔ Tick™ has minimal effect on the environment, reducing our generations environmental footprint, making it the logical choice in acrylic POP/display fabrication.

Green ✔ Tick™ production is with a unique process which reduces the consumptions of water & energy, generating less CO2 emissions, further reducing our carbon footprint.

Features

Mechanical engineers, construction co., transport producers & POP / exhibition displays, all need to meet rising environmental demands. Protective equipment has to offer durability, safety & security, whilst also providing an appearance that harmonizes with the application. That is why these professionals often choose Green ✔ Tick™ acrylic sheet, for machine guards, glazing in the transportation & construction sector, for ice-rink barriers in ice hockey stadiums, or in store security applications. Green ✔ Tick™ acrylic is one of the leading RMMA quality & versatile plastic substrate. It meets with general wear & tear & is easy to machine & fabricate. Green ✔ Tick™ acrylic applications are segments such as POP, display & signage, furniture, exhibitions & transport, domestic applications, with also commercial architecture & construction, industrial applications, and a wide range of lighting applications. The quality and distribution of light & energy efficiency with an LED light source are key requirements in modern lighting systems.

Green ✔ Tick™ is the perfect solution for diverse applications including:

● Picture framing● POP Displays

● Exhibit displays

● Display cases

● Poster advertising protection

● Signage

Grades available:

● Green ✔ Tick™ Gloss (with further grades in development).Specialty Properties are:

● Specially formulated proprietary technology.● Excellent light transmission & optical clarity.

● Perfect cast acrylic finish (no manufacturing lines & inclusions).

● Good mechanical properties - shatter resistant.

● 100% recyclable product.

Specifications

Green ✔ Tick™ acrylic is the ideal substrate to meet these requirements. Its properties –

unsurpassed transparency & brilliance, surface finishes, ease of thermo-forming, meeting

technical & design requirements of lighting engineers & illuminated advertising/POP

signage, lighting manufacturers & architects.

Due to the manufacturing process, GreenTick acrylics contain no plasticizers, heavy

metal salts or halogens, & no levels of chlorine. Green ✔ Tick™ acrylic basic chemical

structures contain no nitrogen compounds or bisphenol A. Green ✔ Tick™ acrylic will

normally emit no toxic or cancerogenic, mutagenic, teratogenic, even in the application of

above the service & distortion temperature (approx. one hundred degrees Celsius). Due to the chemical chain structure, Green ✔ Tick™ acrylic does not react with water & can be

safely used in aquatic applications.

GreenTick acrylic solid sheets are extremely resistant to standard mechanical

methods during installation & in application. Green ✔ Tick™ acrylic sheets offer eleven

times the impact strength of conventional domestic glass.

Standard Product Range:

Ticknesses:

●2.0 – 30.0mm (0.079” 5/64” – 1.18” 1 3/16”) (Other thickness available on request)Sheet Dimensions:

● 1830 x 1220mm (6’ x 4”)● 2440mm x 1220 (8’x4’)

● 2490mm x 1830mm (8’ x 6’)

● 3020mm x 2020mm (9' 10 7 / 8 " x 6' 7 1 / 2 ")

● 3050mm x 2050mm (10' 1 / 16 " x 6' 8 11 / 16 ")

Protective Masking:

● Pressure Sensitive Paper – (Printed Paper 1 side) or (Plain Paper 2 sides).● PE Masking - (Transparent Green/Clear) or (Clear/Clear) satin surface finish.

See full Data Sheet

Learn More

Mechanical engineers, construction co., transport producers & POP / exhibition displays, are all required to meet rising sustainability demands. Protective equipment has to offer durability, safety & security, whilst also providing an appearance that harmonizes with the application.